The video of the world’s largest tunnel boring machine has appeared on the Internet recently. It was affectionately called Bertha. This huge mechanism, weighing more than 6,000 tons, made a tunnel under Seattle at the depth of 61 meters.

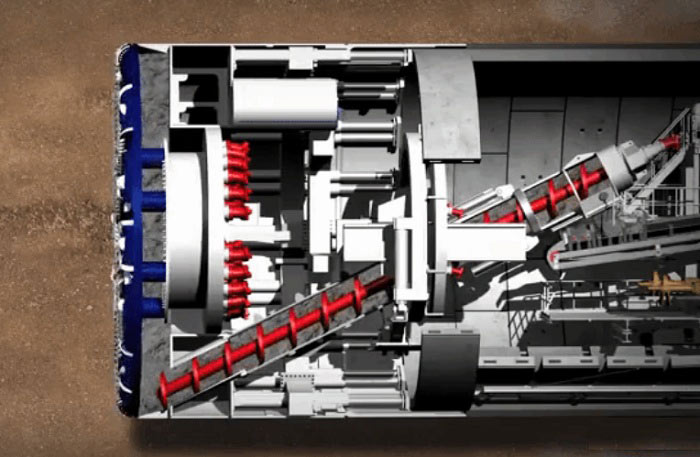

Four years ago, Washington State Department of Transportation ordered the Japanese Hitachi Zosen Corporation to build the world’s largest tunnel boring machine Bertha. Its weight is 6,350 tons, its width is 17.5 meters, and length – 99.3 meters. This giant machine was engaged in making a tunnel in Seattle, which will then be modified for the State Route 99 highway.

The tunnel boring machine was launched in 2013, but it broke down soon. It took many months to fix it. The cost of repairs and the downtime cost the authorities $223 million, despite the fact that the machine was purchased for $80 million. Bertha fulfilled its task: it laid a 3-kilometer-long tunnel.

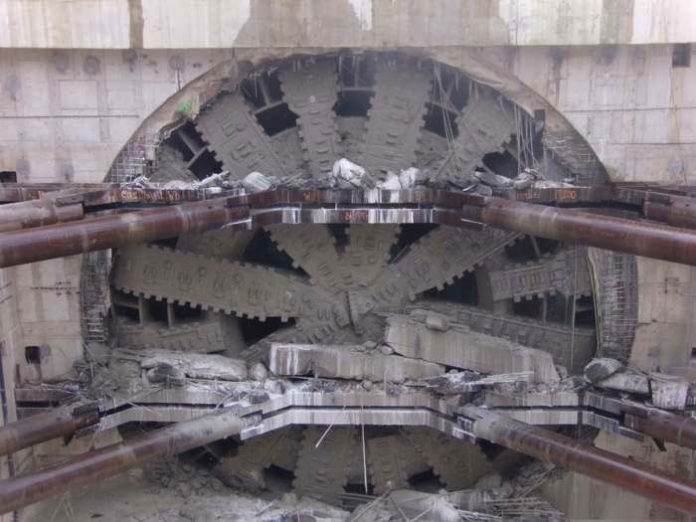

The cutter head of Bertha has 700 steel blades moving in different directions. Some of them are fixed in the front end. The weight of each cutting element is 34 kg. During one revolution (1 minute), the machine cuts up to 12 tons of soil.

Bertha not only digs the tunnel but also builds it. Not to spoil the work done and to prevent the walls from collapsing, the rear part of the huge machine was equipped with pumps removing water, and mechanisms that lay concrete sections. These segments form rings, supported by jacks. The builders work so well that laying a ring takes no more than an hour. It may seem funny, but they get to know what operation to perform with the help of music. Each melody means a certain stage of work.

Project managers report that the tunneling machine will be dismantled: some parts will be sold to the manufacturer or recycled, and the bulk will be sent to the local iron works for re-melting. The resulting material will be used to build a motorway in a paved tunnel. The two-level highway is planned to be finished by 2019.