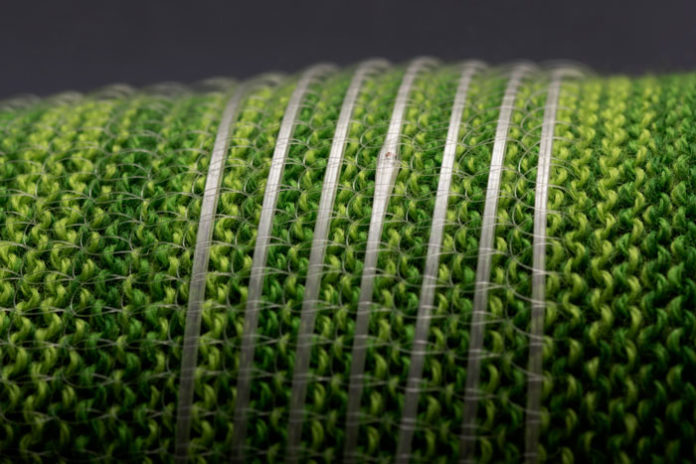

The world’s first programmable fiber with digital capabilities to control, store, analyze data, as well as record the person’s activity was created by engineers from the Massachusetts Institute of Technology through integrating it in the fabric of the garment. Physically, digital fiber is a polymer thread that can be threaded into a needle and woven in a pattern of varying complexity into the standard fabric of a person’s everyday clothing.

Digital fibers expand the ability of fabrics to monitor the processes taking place in the human body. The data obtained can be used to track physical performance, draw up medical reports on health status and for the early diagnosis of diseases. In addition, the user can store standard files on the clothes, for example, the wedding music played on a significant day.

Before the development introduced by a group of engineers and scientists at MIT, electronic fibers had been analog, capable of transmitting or interrupting an electrical signal. Digital fibers can now encode and process discrete bits of information as 0s and 1s.

To implement the idea of the researchers, led by Professor Yoel Fink, hundreds of square microchips were placed in the mold before making the polymer fiber, converting the fabric into a microcircuit. After forming the thread, the scientists were able to obtain a fiber with a continuous electrical connection between the chips covering tens of meters.

This digital fiber can be used for a variety of purposes, woven into the common fabric of everyday wear. In the simplest case, the new fiber can be used as an information carrier. During testing, the digital fiber was able to keep a 767-kilobit full-color short video file and a 0.48-megabyte music file for two months without an additional power supply.

By increasing the length of the thread, it is possible to form devices with the functions of a neural network or a computer. MIT experts have already created a system of 1,650 joints integrated into the armpit of the shirt. As a result, the digital application was able to record data on the temperature and humidity of the human skin surface, and after using machine learning technology, it even recognized with an accuracy of 96% the type of physical activity that the wearer is engaged in.

The digital fabric is able to withstand up to 10 wash and dry cycles and does not hinder the user’s movement. The fiber is controlled by a small external device, so the next step is to develop a new chip as a microcontroller that can be embedded directly into the fabric.